Rockwell Automation Training Programs

Our Rockwell Automation training programs are designed to provide a structured learning path, from foundational skills to advanced applications. The following sequence of training courses will help you become proficient with Rockwell products, including PLC programming, VFD control, FactoryTalk software, HMI development, and SQL for data management.

1. Rockwell PLC Programming

This foundational course covers the essentials of Allen-Bradley PLC programming, including ControlLogix, CompactLogix, and MicroLogix series. Learn basic ladder logic, function block programming, and structured text to design and troubleshoot control systems.

- PLC Basics: Understand the principles of PLC architecture and components.

- Ladder Logic Programming: Write and troubleshoot ladder logic programs for Rockwell PLCs.

- Function Block Programming (FBD): Learn to use function blocks for more complex control applications.

- Structured Text (ST): Master structured text for creating more sophisticated control algorithms.

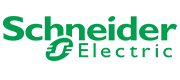

2. Rockwell VFD Control

Understand how to control motors and other machinery with Rockwell VFDs. This training will help you configure and optimize PowerFlex VFDs for motor control applications and integrate them into your PLC systems for closed-loop operation.

- VFD Basics: Learn how VFDs control motor speed and torque.

- PowerFlex VFD Configuration: Configure PowerFlex 525 and PowerFlex 750 drives for motor control.

- Closed-Loop Control: Implement feedback control for optimal motor performance.

- Integration with PLCs: Integrate VFDs with Allen-Bradley PLCs for precise control of motors and processes.

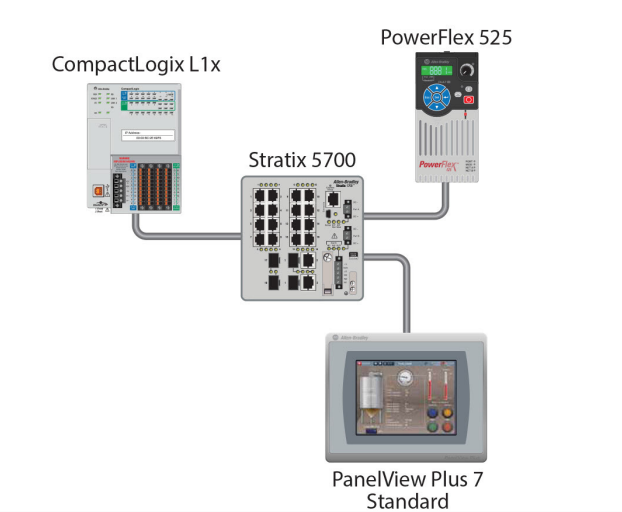

3. FactoryTalk Software Training

Learn how to use FactoryTalk View for creating and managing Human-Machine Interface (HMI) applications, and how to integrate them with Rockwell Automation PLCs for real-time data collection, process control, and monitoring.

- FactoryTalk View ME: Design and deploy HMI applications for PanelView displays, managing real-time data from PLCs.

- FactoryTalk View SE: Create SCADA systems for plant-wide monitoring and control, with multiple operator stations.

- Data Logging: Implement data logging in FactoryTalk for historical data analysis and trend monitoring.

- Alarm Management: Set up alarm systems and event logging in FactoryTalk for efficient operator feedback.

4. HMI Development with FactoryTalk

This course focuses on designing user-friendly HMI screens and integrating them with Rockwell PLCs. You'll learn to create visualizations, control elements, and alarms to improve operator interaction with industrial processes.

- Screen Design: Create clear, intuitive HMI screens that improve operator efficiency.

- Tag Configuration: Configure tags in FactoryTalk for data exchange between HMI and PLC.

- Interactive Controls: Build interactive controls such as push buttons, sliders, and switches for real-time control of processes.

- Alarm Management: Implement alarm systems within HMI applications to notify operators of faults or critical conditions.

5. Studio 5000 & Advanced PLC Programming

Take your PLC programming skills to the next level with Studio 5000. Learn advanced topics such as Motion Control, Integrated Architecture, and Safety Logic with GuardLogix controllers.

- Motion Control: Use Studio 5000 to program motion controllers for complex multi-axis motion systems.

- Integrated Architecture: Integrate multiple control systems into a single architecture for complex automation environments.

- Safety Systems with GuardLogix: Program and configure safety systems to comply with industry safety standards (e.g., ISO 13849).

- Tag Structure and UDTs: Develop custom tag structures and use User-Defined Data Types (UDTs) for organizing data in large projects.

- HMI Integration: Connect and configure Human Machine Interfaces for seamless operator interaction.

- Data Logging & Diagnostics: Implement advanced logging, diagnostics, and troubleshooting features within Studio 5000.

6. SQL for Industrial Data Management

This training will teach you how to use SQL for storing and querying industrial data from Rockwell systems. Learn how to integrate SQL databases with FactoryTalk and PLC systems to manage large datasets for reporting and analytics.

- SQL Database Design: Learn how to design and structure SQL databases for storing process data from PLCs and SCADA systems.

- SQL Queries for Data Retrieval: Write SQL queries to extract process and alarm data from databases for analysis and reporting.

- Integration with FactoryTalk: Integrate FactoryTalk with SQL databases for seamless data logging and retrieval.

- Data Analytics & Reporting: Use SQL and reporting tools like Power BI to analyze process data and generate reports for decision-making.

Our Rockwell Automation training programs offer a comprehensive learning path, from basic PLC programming to advanced data management, to ensure you have the skills to implement and maintain modern automation systems. Get certified and take your career to the next level!